sales@timesaramid.com

World-Leading Manufacturing Technology

Technology-Driven Manufacturing Excellence

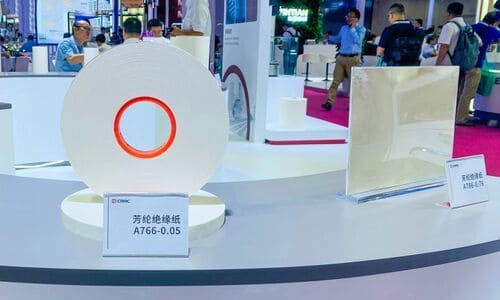

A new global standard in aramid paper quality, consistency, and reliability, delivered through our internationally advanced, fully automated production lines.

Shaping the future of electrical insulation

Global Leader in Paper-Based Electrical Insulation

Aratech stands apart as one of the few companies worldwide with fully independent R&D in aramid paper-based solutions, we have mastered breakthrough technologies including dry-jet wet-spun fiber preparation, high-consistency forming, hydraulic headbox long-wire forming, and electromagnetic induction high-temperature roll pressing — redefine what is possible in aramid paper manufacturing.

Manufacturing Excellence

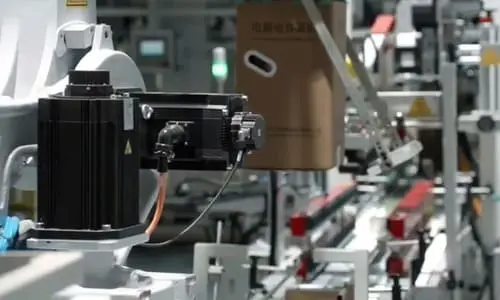

Zero-Defect Manufacturing Backed by Intelligent Automation

Our advanced fully automated manufacturing is not just how we make our aramid paper—it is our guarantee of world-class quality and consistency.

Our production base integrates state-of-the-art wet-forming aramid fiber lines, high-temperature calendering systems, and smart digital control centers with over 3,000 logic control points. Every roll of aramid paper is formed, pressed, dried, and finished under tightly monitored conditions to ensure consistent density, dielectric strength, and mechanical performance.

From fiber dispersion to high-temperature finishing, every step is optimized through precision automation and data-driven process control, ensuring unmatched uniformity and efficiency.

Advanced Manufacturing Processes

Excellence Built Into Every Layer of Production

Expert-Driven Automation for World-Class Quality

True manufacturing mastery is the seamless fusion of the best technology with the best talent, our production lines are managed and optimized by a dedicated team of highly skilled process engineers and technicians. Their deep expertise in aramid science ensures our systems are always running at peak efficiency and producing the highest quality material possible.

Mastering the Art of Automated Manufacturing

Advanced Inspection & Quality Control System

Commitment to Continuous Innovation

Manufacturing for the Future

Through continuous process optimization, intelligent automation, and advanced material science, we keep pushing the limits of aramid paper performance.

Our goal is not only to produce materials — but to redefine standards for Electrical Insulation Properties.